Projects

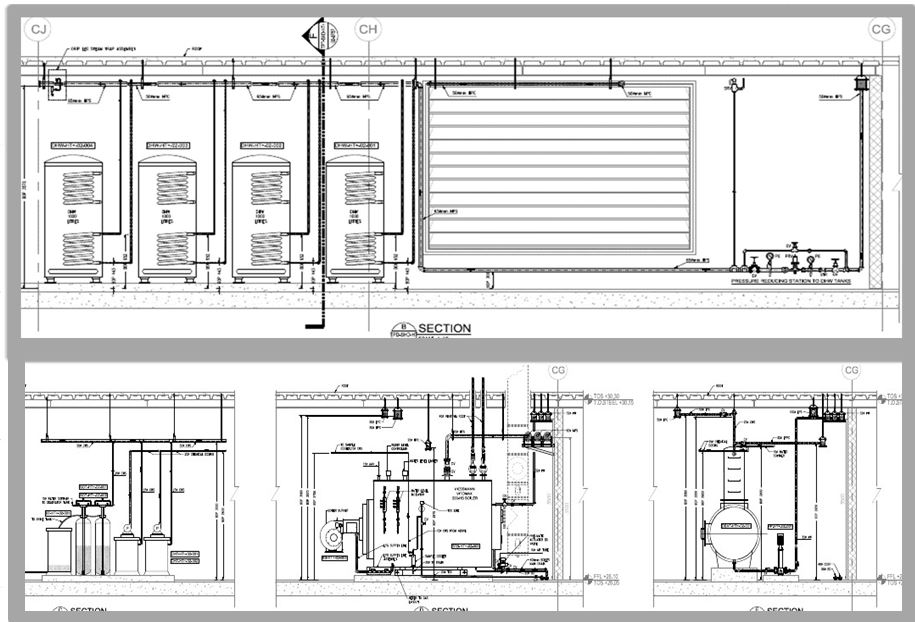

Client: Hamad Medical

Project Type: 400 Bed HOSPITAL Service Type: Design Build Location: AL WAKRA, Doha Qatar.

System Type: Steam Boilers / Domestic Hot Water System. Manufactured by: HURST Boiler, USA

➢ Three High Pressure STEAM BOILERS / 18,000.00 KG/HR design build, supply, construction, testing and commissioning, Training, handing over.

➢ Subcontracted, Managing, designing, constructing, operating, testing and commissioning

➢ High pressure Boilers / 3 pass fire tubes., 2 Tube Heat exchangers,2 plate heat exchangers Spirax Sacro, blow down vessel, steam reducing stations, steam header and distribution, steam flow meters, steam traps.

➢ Over 4 KM of piping supply and return condensate. Expansion tanks, Deaerator Tank, GRUNDFOS high pressure water supply pumps. high tech components and equipment’s

➢ Serving Laundry rooms. Kitchen, CSSD. Sterilization Center Department,

Auto Clave Medical Waste Treatment, Domestic Hot water.

➢ Installation and site supervision of 100 skill trades, trouble shoot technical problems, or system malfunction and errors.

➢ Conduct system inspections, sequences of operation and assembly prior to the final approval, Coordinate and resolve any issue with the consultant, safety officer, and the client.

➢ Prepare and conduct all training materials, and provide the necessary training for the end user staff. Prepare and review shop drawings and AS BUILT.

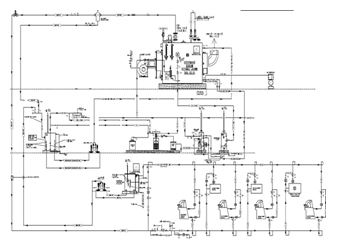

Client: Qatar Petroleum

Project Type: Qatar Petroleum District Service Type: Design Build

Location: West Bay, Doha Qatar.

System Type: Steam Boilers, Domestic Hot Water System.

➢ Steam System & Boilers Design and Built, Qatar Petroleum District

➢ Three High Pressure Boilers / 5000 KG / HR /steam, design built, structure and design modification.

➢ Managing, designing, constructing, saturated steam system.

➢ Fire tubes, blow down vessel, steam reducing stations, steam header

and distribution, steam flow meters, steam traps, Expansion tanks, Deaerator Tank, GRUNDFOS high pressure water supply pumps.

➢ Control Panels, high tech components and equipment.

➢ Installation and site supervision of 100 skill trades, trouble shoot and resolve any technical problem, or system malfunction and errors.

➢ Conduct system inspections, sequences of operation and assembly prior to the final approval,

➢ Coordinate and resolve any issue with the consultant, safety officer, and

the client. Prepare and conduct all the training materials, and provide the necessary training for the end user staff.

➢ Steam Required Services, Laundry Room, 4 / 1000 liters indirect Hot

water Storage Tanks, built in coil tube exchanger.

➢ Prepare and review shop drawings and AS BUILT for final approval.

Client: Msheireb Properties

Project Type: Resort & Spa

Service Type: Design & Engineering Location: Doha Qatar.

System Type: Steam Boilers

➢ Steam Boiler, High pressure, Laundry Room Services.

➢ Engineering Design, complete documents submittal,

➢ Saturated steam system, high pressure Boilers, blow down vessel, steam reducing stations, steam header and distribution, steam flow meters, steam traps, Expansion tanks, Deaerator Tank,

➢ Inspections, sequences of operation and assembly prior to the final approval,

➢ Coordinate and resolve all design issues with the consultant,

Client: QATAR FOUNDATION

Project Type: STUDENT HOUSING Service Type: Design Build

Location: Education City, Doha Qatar. System Type: SOLAR Water Heating. Manufactured by: AMK SOLAC Switzerland

➢ 22 Solar Water Heating Systems in12 buildings Evacuated Tubes.

➢ Subcontracted, Managing, designing, constructing, operating, testing and commissioned.

➢ 2 solar water heating systems per building, preparing all the technical and

documents submittal, including equipment’s and materials selection, installation, and site Project Management (50 skill trades, 10 Engineers / Supervisors)

➢ Conduct system inspections, sequences of operation and assembly prior to the final approval.

ØPLC programing & Control including all the Electrical connections, and Circuit Panel.

➢ Coordinate and resolve any issue with the consultant, safety officer, client.

➢ Prepare and conduct all the training materials, and provide the necessary training for the end user staff. Prepare and review shop drawings and AS BUILT.

Client: QATAR FOUNDATION

Project Type: STUDENT HOUSING

Service Type: Design Build

Location: Education City, Doha Qatar.

System Type: WIND TURBINES (10KW EACH)

Manufactured by: URBAN GREEN ENERGY NY, USA

➢ Manage, design, construct, operate, test and commissioned 6 Wind Turbines

➢ Vertical Rotation type, capacity 10 KW each, almost 0 DBA.

➢ 25 meters High, slip sections tower, and one vertical axis with generator attached to 3 verticals aerodynamics blades.

➢ Design & engineering and installation of the system. electronics which will include 3 protection boxes, 3 inverters, and 3 diversion load per each turbine, and other electrical components

Client: Hamad Intranational Airport

Project Type: Airport

Service Type: Engineering & Design Location: Doha Qatar

System Type: Aircraft Hanger Smoke Curtains

- Custom Built Project, CP 26 mega structure Aircraft Maintenance Hanger to host 380 Airbus planes, 5 Bays dedicated to test and maintain the largest aircraft. The project requires to design and install a smoke curtains barrier between each bay, up in the hanger structure ceiling, the method was tailored made to attach and mount the smoke curtains against the hanger ceiling steel trusses 50 meters above the hanger floor.

- System 2 : Vehicle guard Rail along the airport departure road, stretched 3 km , the application required a bending method to shape the stainless steel sections. Including the mounting bases. With embedded lighting system.

Client: Muscat International Airport

Project Type: Airport

Service Type: Engineering & Design Location: Muscat Oman

System Type: Air Displacement Units

- Custom Built Project, The terminal is to be served with a displacement system implemented in a unique design under the seating bench, with VAV, Air control thru black foam, And The system is to be integrated with the building design as envisaged by the architects and the interior design teams.

- The total supply air is 70,000 m3/h and the temperature difference between the space and the supply air is 3 - 4 K., A solid LSE stainless steel grid, which consists of reinforced triangular profile 2.3 mm wide was used, and for aesthetic reasons, a free area of 50 % was selected.

Client: North Terminal Airport

Project Type: Airport

Service Type: Engineering & Design Location: DETROIT USA

Project Type: Food Court, 12 Restaurants

- Design and build a group of food and beverage outlets, in Detroit Metro airport new North terminal. Including engineering & design . permits and approval .

- Provide and manage all level of the construction process and phases, plus a full representation of the client interest and expectation.

- Our team dedicated time, effort, and knowledge to implement the necessary steps and program to achieve and meet budget and schedule, plus client expectations.

Our Philosophy

We believe what makes us different from other engineering firm is our ability to deliver a tailored, value engineered and personal service to each client.

USA Main Office

- 601 BRICKELL KEY DR SUITE 700, MIAMI, FL 33131

- Office : 1(786) 779-4000

- Office: 1(305) 787-3314

- Email : info@prizmaenergy.com